Page 5 of 8

Re: my 65 re-paint!!

Posted: Thu Aug 28, 2014 10:43 pm

by Shaunp

ozbilt wrote:nassi wrote:Shaunp wrote:Yeah if they are worn out the bonnet will sit at the rear when you close it you can push it down

On 65/66 and probably later ones you can actually rotate the hinge to overcome the "high at the back syndrome". With the hood on, loosen two bolts and push the front of the hood up, this forces the back of the hinge down and raises the front of the hinge. As you can guess its easier with two people.

i have lost count of the hoods I have fitted to these cars and only found one hinge where this dosnt work. It also works on early Falcons, in fact thats where I learnt it.

& if you run out of adjustment with that trick, you then move to the British idea of a shim between the hinge & hood on the front bolt location ......

E type jag bonnets are adjusted with shims , tin snips and a sanding disc. when you buy them they are too long, you get them to kind of fit then cut the back off with snips I then use one of those red sanding discs on a 7' backing and jamb it between fire wall and bonnet, sand it till the gap is perfect. Back edge of an E bonnet is not folded just a raw edge.

Re: my 65 re-paint!!

Posted: Thu Aug 28, 2014 11:33 pm

by mjb0015

Shane hinges look great!!

Think Im going to get some new ones as mine have a fair bit of play.

Xpconner and hybrid great pics of your cowl!! Im still in two minds as to either spot repair or replace the cowl, looks like a big job, I will have a look under the dash, if it looks like crap I will most likely replace it, found out there is about 160 spot welds to drill looks like fun!

When re-welding do you guys go with a MIG and just weld where the old spot welds were?

Re: my 65 re-paint!!

Posted: Thu Aug 28, 2014 11:47 pm

by mjb0015

Cool hood hinge trick Nassi will give this a go, as my hinges are the same the back of the hood rises up and pushing down on the hood gently can make it flush again.

Re: my 65 re-paint!!

Posted: Fri Aug 29, 2014 1:20 am

by ozbilt

mjb0015 wrote:

Xpconner and hybrid great pics of your cowl!! Im still in two minds as to either spot repair or replace the cowl, looks like a big job, I will have a look under the dash, if it looks like crap I will most likely replace it, found out there is about 160 spot welds to drill looks like fun!

When re-welding do you guys go with a MIG and just weld where the old spot welds were?

Actually not that bad a job. Just boring (using a pun) drilling the resistance spot welds .....

The complete replacement sections are nice. Just buy the upper & lower NOT welded together.

MIG it back together.

Re: my 65 re-paint!!

Posted: Fri Aug 29, 2014 8:02 am

by hybrid

Yep, just a MIG.

I used one of these to punch all the holes in the new parts.

http://www.ebay.com.au/itm/17-Piece-Hea ... d3d&_uhb=1

Re: my 65 re-paint!!

Posted: Fri Aug 29, 2014 8:39 am

by nassi

Re: my 65 re-paint!!

Posted: Fri Aug 29, 2014 9:13 am

by ozbilt

I have had both for years, but always grab the one nassi linked .....

Re: my 65 re-paint!!

Posted: Fri Aug 29, 2014 9:36 am

by hybrid

Yeahhhh crap. I wish I had found one of those when I was doing mine.

Although my hand is fairly well weathered... if you know what I mean

Re: my 65 re-paint!!

Posted: Fri Aug 29, 2014 10:43 am

by xpconnor

I am a tight ass so I just drilled all mine by hand and then took the burs off the back with a flap disc.

There was a good write up about how to do the cowl on the mustang monthly website that I can't find the link to anymore and in my Caroline build thread I go through what I did. Kerry also did a write up in a build thread he was doing but I can't remember which car it was for.

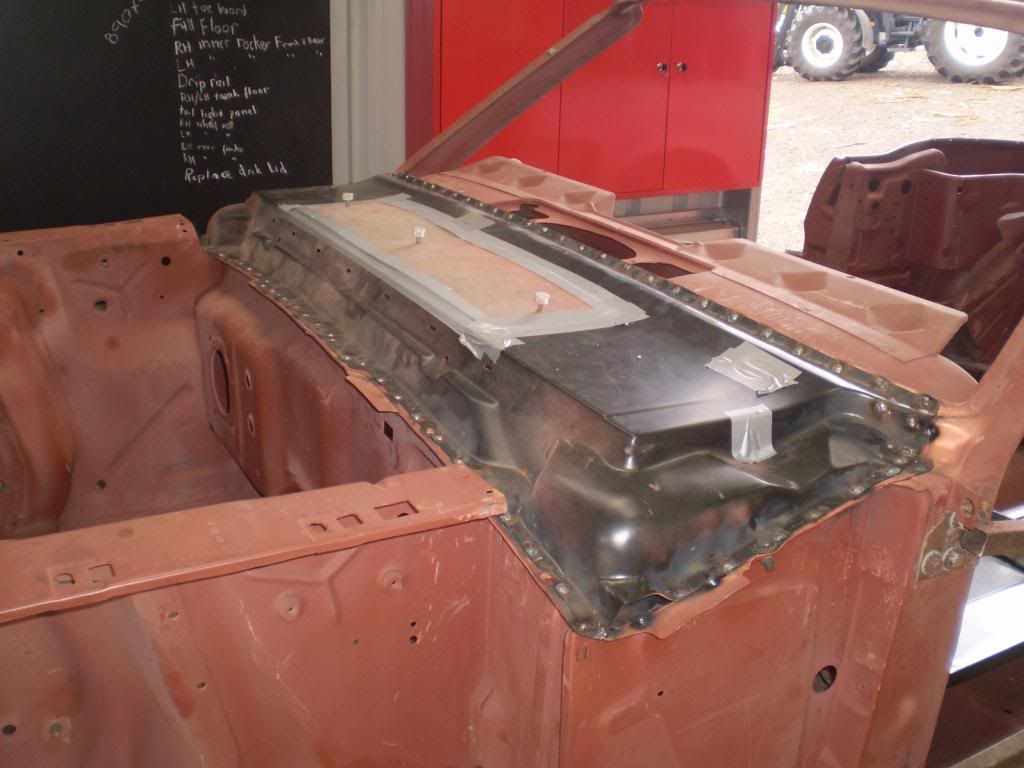

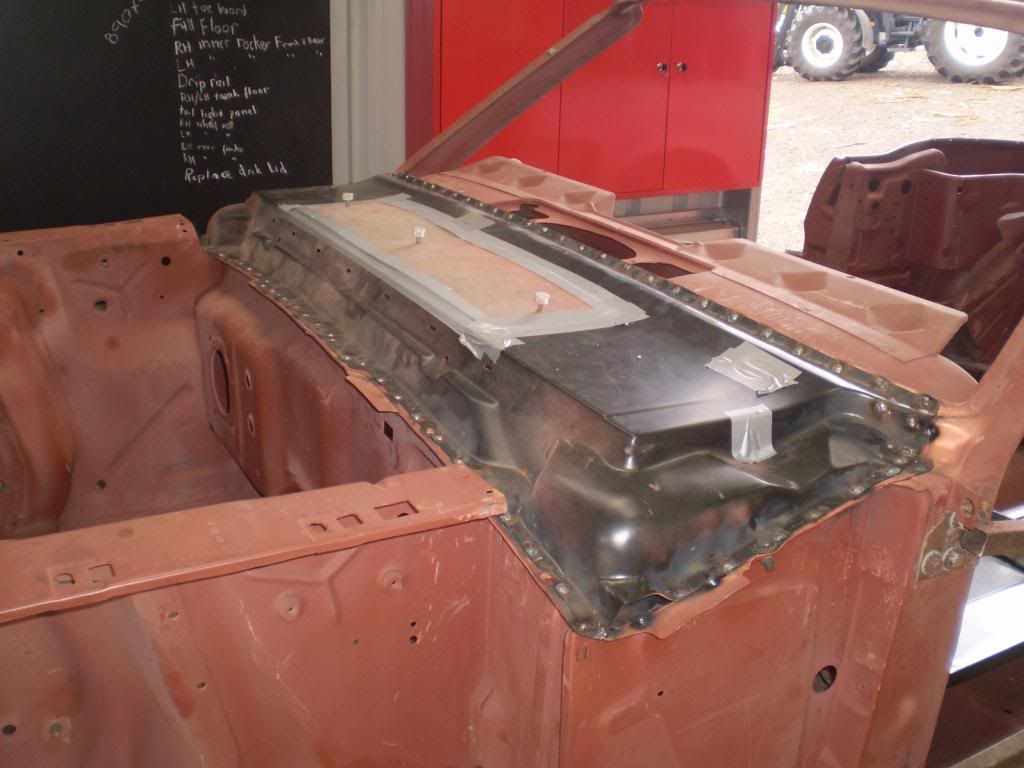

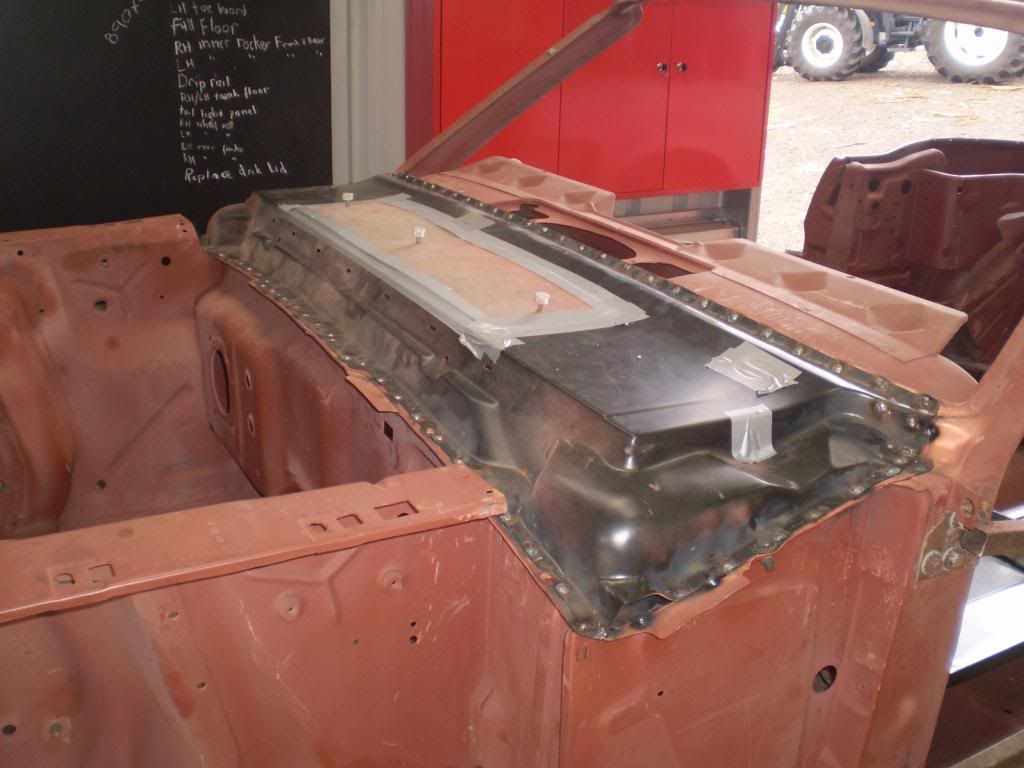

I had no experience with panel beating and was able to replace the cowl and as Kerry said it is not hard just time consuming. The replacement cowl is probably the best fitting panel I have worked with closely followed by the full floor pan replacement. Depending on your skill level I would actually say it is probably easier to just replace the entire thing then do the patches like Shaun has done. Only need to do plug welds if you replace the whole thing.

Re: my 65 re-paint!!

Posted: Fri Aug 29, 2014 9:14 pm

by Shaunp

I only did the patches because I'd already converted the wipers to RHD.

Re: my 65 re-paint!!

Posted: Sat Aug 30, 2014 1:00 am

by mjb0015

Yeh that air punch looks like it will do the job nice, also noticed the air nibbler how good is this little tool for cutting steel will get both of these!! thanks for the tips !!!

Mark

Re: my 65 re-paint!!

Posted: Sat Aug 30, 2014 1:05 am

by mjb0015

Yeh Xp recon I will replace the whole cowl, does seem really straight forward, haven't had much experience in this before but Im learning. What did you mean do the plug welds if I replace the whole thing? Do you mean the drain plug holes at either end of the cowl?

Mark

Re: my 65 re-paint!!

Posted: Sat Aug 30, 2014 6:57 am

by ozbilt

mjb0015 wrote:What did you mean do the plug welds if I replace the whole thing? Do you mean the drain plug holes at either end of the cowl?

Mark

No. We mean the welds that fill a hole like what xpconnor did on his plenum .....

Re: my 65 re-paint!!

Posted: Sat Aug 30, 2014 11:00 am

by nassi

mjb0015 wrote:Yeh that air punch looks like it will do the job nice, also noticed the air nibbler how good is this little tool for cutting steel will get both of these!! thanks for the tips !!!

Mark

If you mean the tool on the back of the punch it is not a nibbler but a stepping tool. It recesses the edge of a panel so the next piece can overlay it.

Re: my 65 re-paint!!

Posted: Sat Aug 30, 2014 11:04 am

by xpconnor

ozbilt wrote:mjb0015 wrote:What did you mean do the plug welds if I replace the whole thing? Do you mean the drain plug holes at either end of the cowl?

Mark

No. We mean the welds that fill a hole like what xpconnor did on his plenum .....

The plugs welds are what you fill all the holes you're going to punch in the new plenum when you weld it in place. People tend to call them a spot weld but technically the spots welds are done by a machine and are what the factory uses without the need to punch a hole in the steel first.

If you replace sections then you will have to seam weld the new sections in, clean all the welds up and then plug weld the top of the cowl back on. For me that is a lot more work.